PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

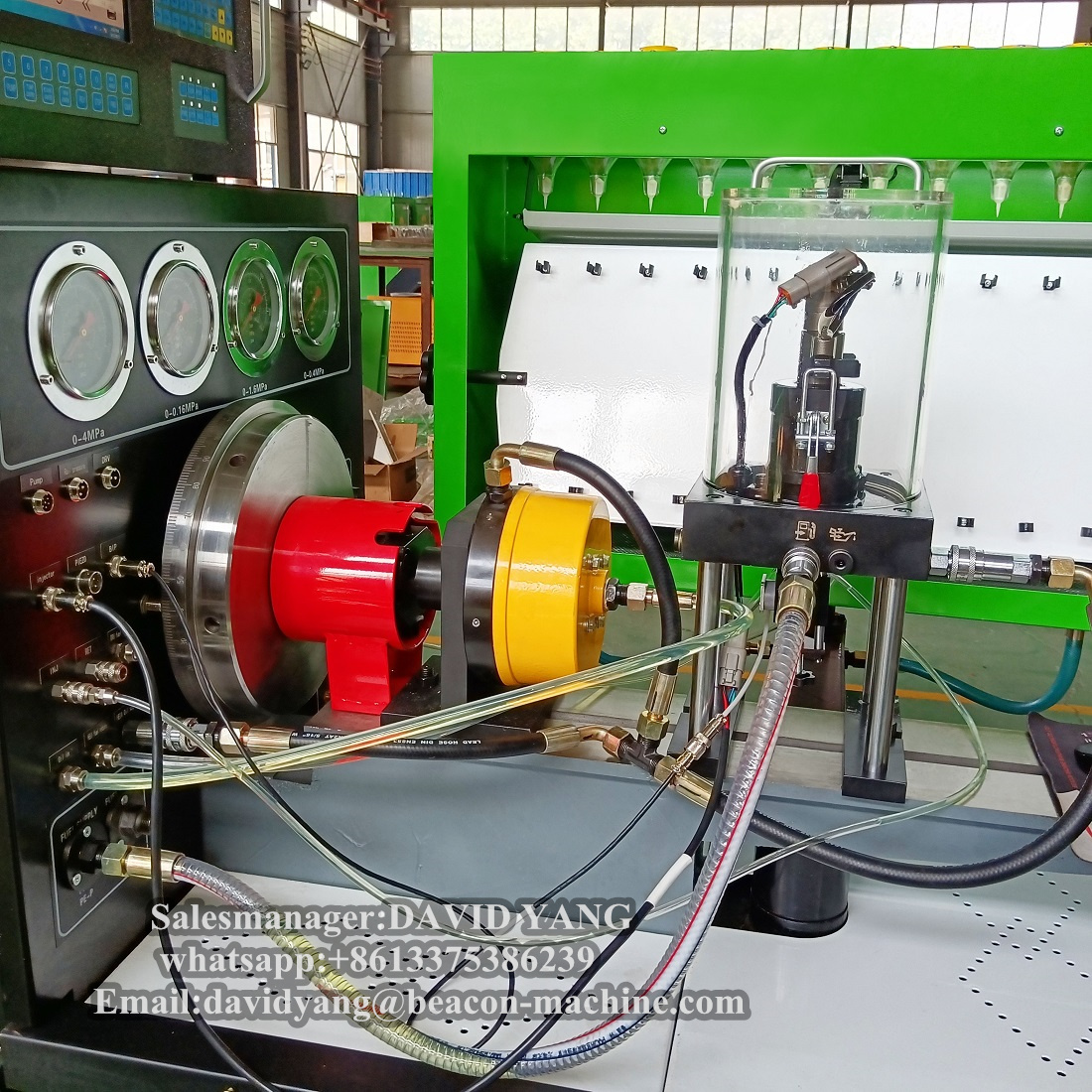

CRS900S is a newly designed multi-function machine that is controlled by computer to achieve fully automatic testing. It can test common rail injectors, common rail pumps, and mechanical pumps. It can also add various special functions such as EUIEUP,HEUI,VP37/VP44,RED4 pump test.

0086-18253885135

CRS900S Mechanical Injection Pump Common Rail CRI CRP Injector Pump Test Bench

Main function

1. Measurement of each cylinder delivery at any speed.

2. Test point and interval angle of oil supply of injection pump.

3. Checking and adjust the mechanical governor.

4. Checking and adjusting the distributor pump.

5. Experiment and adjusting of behavior of supercharging and compensatory device.

6. Measurement of oil return of distributing pump

7. Testing of the electromagnetic valve of distributor pump.(12V/24V)

8. Measurement of the internal pressure of distributor pump.

9. Checking of the advance angle of advance device.(on request)

10. Checking the sealing of injection pump body

11. Install tube of auto-sucking oil supply can check on oil supply pump(including VE pump.)

12. Checking the travel of stroke (on request)

10. Built-in air resource;

CHARACTERISTICS

1. Chaning frequency changing rotational speed

2. Low fall of rotational speed and high output torque

3. High measurement precision;

4. The functions of over voltage, overload and short circuit protection;

5. Ten classes Rotation speeds presetting;

6. Constant temperature controlled;

7. Ultra low noise;

8. Operating position: arbitrary side of the two work sides of the test stand;

9. Rotation speed, count, temperature, air pressure, advance angle and rack travel are measured and controlled by computers in real time, then displayed by 17″CRT or on request (17 LCD touch screen).

10. Built-in air resource;

11. All data can be made into reports and printed;

12. Automatically generating and displaying speed characteristics curve;( tooth bar stroke)

13. The data of the pumps can be saved, modified and obtained pump database;

14. It is very easy to find the data of the pumps in pumps database;

15. Windows operating system.

CAN TEST HEUI CAT C7 C9 3126B INJECTOR:

Test Mechanical injection pump:

WITH NEWEST COMMON RAIL TEST SYSTEM(MORE THAN 10000 ORIGINAL INJECTOR PUMP DATA)

English

English Русский

Русский Español

Español