PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

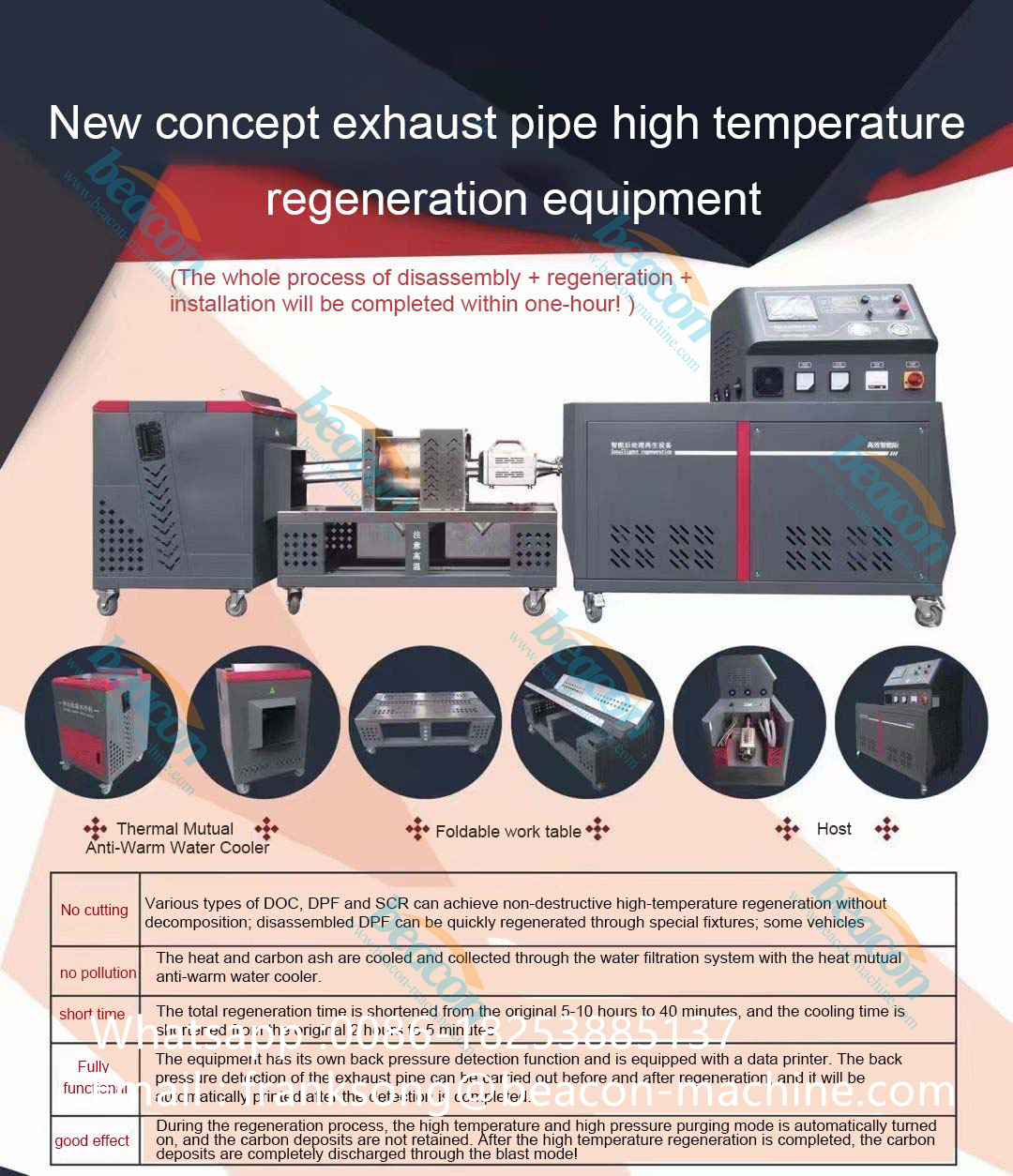

Industrial Diesel Engine Dpf Cleaner Cleaning Equipment Dpf Cleaner

0086-18253885135

DPF-CL Intelligent post-processing regeneration intelligent collar version

Special attention; Before starting the regeneration, perform a pressure test on the equipment to determine if there is gas discharge at the tail end of the exhaust pipe and if there is any leakage at the connections. After the regeneration back pressure exceeds 40KPa, the equipment will alarm and check if the carrier has been washed, displaced, sintered, and does not have the ability to regenerate. It is recommended to replace the carrier.

Handling methods; First, clean or blow out the exhaust pipe until the back pressure drops below 35KPa, and perform preliminary dredging at a regeneration temperature of around 200 degrees until gas is discharged from the tail end of the exhaust pipe! Only then can high-temperature regeneration be carried out.

Please check the alarm bar in a timely manner when the device is in an alarm state.

Environmental conditions for use

1) Environmental temperature; 0 ℃ -50 ℃;

2) Relative humidity 0% -65%;

3) Ventilation, no vibration, no dust, flammable gases, oil mist, dripping water;

4) It is strictly prohibited to stack flammable and explosive materials within 1 meter around the equipment!

5) It is recommended to use the equipment in an outdoor workspace and install an exhaust mechanism for indoor use!

English

English Русский

Русский Español

Español