PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

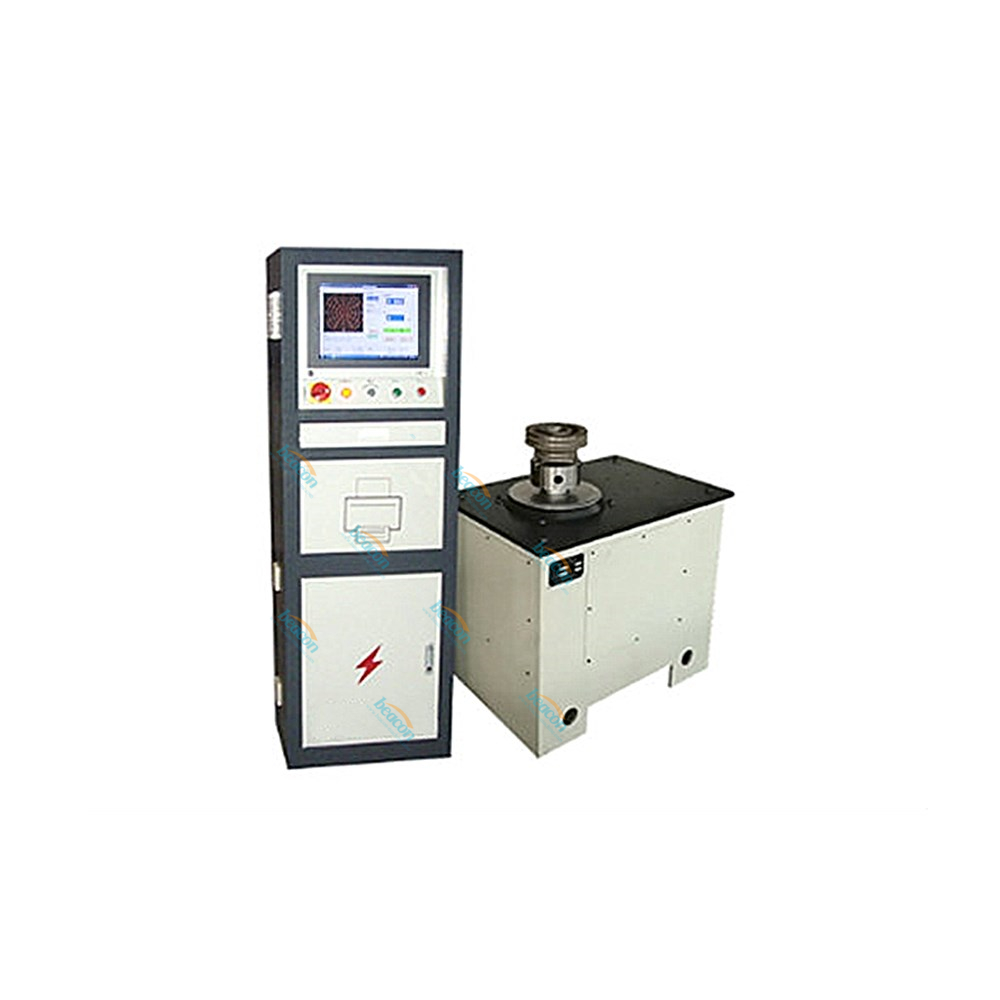

YLD-20S vertical single plane flywheel rotor dynamic balancing machine

0086-18253885135

1.Features:

General hard bearing dynamic balancing machine strictly according to GB/T 4201-2006 to produce, using semi hard bearing, belt driven, screen display structure, industrial control computer processing the data. 19 inches LCD screen display unbalance amount, phase angle and real-time rotating speed. It is widely used in paper making machine, textile machine, agriculture machine, electric motor, blower fan, etc, can measuring balance on single interface, suited for plate work-piece, center of gravity overhung rotor.

2.Main technical index

Way of driving: frequency converter+motor+V-ribbed belt

Measuring system: independent developed dynamic balancing machine special measuring software, visual display, measurement accuracy.

3.YLD-20S dynamic balancing machine technical index:

1)weight of work-piece (kg): 1-20

2)Max diameter of work-piece (mm): φ500

3)Min achievable residual unbalance amount(gmm/kg): ≤3

4)Unbalance reduction ratio(%): ≥90

5)Rotating speed(r/min): 200-1500

6)Motor power(kw): 1.1

7)Drive mode: V-ribbed belt driven

8)Work environment: temperature: -5---45℃; humidity: 0-85%

4.Device configuration:

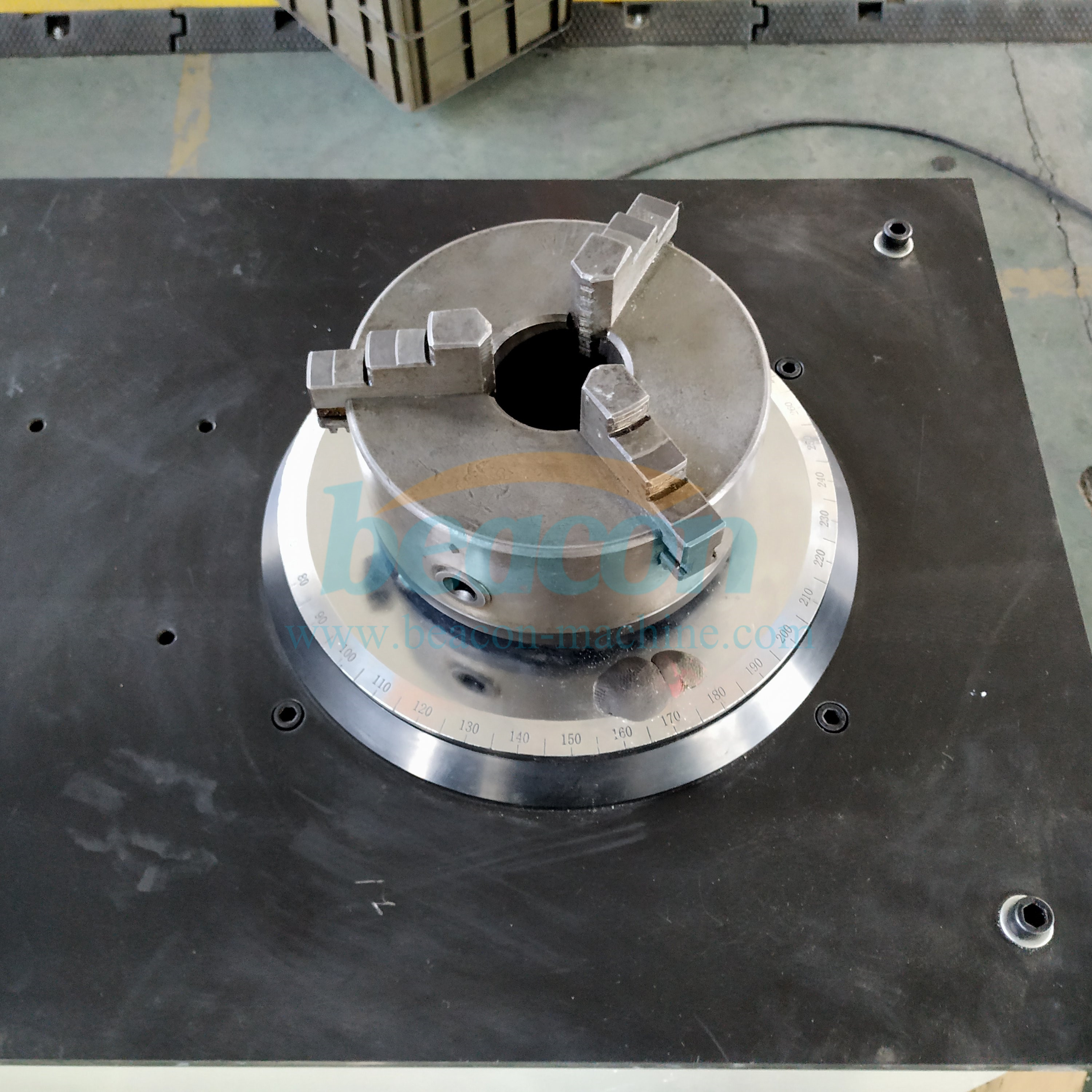

1) On lathe bed installing bearing frame and principal axis

Swing frame material is Mn65, can exactly collect vibration signal, integrated structure, there is piezoelectric sensor assembly behind elastic beam, used to measuring the shake of swing frame.

2)driven part:

One piece unsplit bed-plate

One set principal axis

One set 1.1kw motor

One piece aluminum dial

One set reference signal sensor

3)strong current system include:

Operation control panel ahead control cabinet installed power switch, start stop knob, inside vertical industry cabinet installed strong current controlling circuit board, air switch, IVNT frequency converter, converter dedicated filtering device, all above low-voltage components adopt domestic famous brands.

4)measuring system include:

One set 32 bits industrial control computer;

One set 19 inches flat panel LCD monitor;

One piece LENOVO anti-interference keyboard, one piece mouse;

One set high-end electronic control cabinet;

A set of foundation bolt, wedge iron for leveling, and tools with the machine;

A set of balancing machine software and technical manual.

English

English Русский

Русский Español

Español