PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

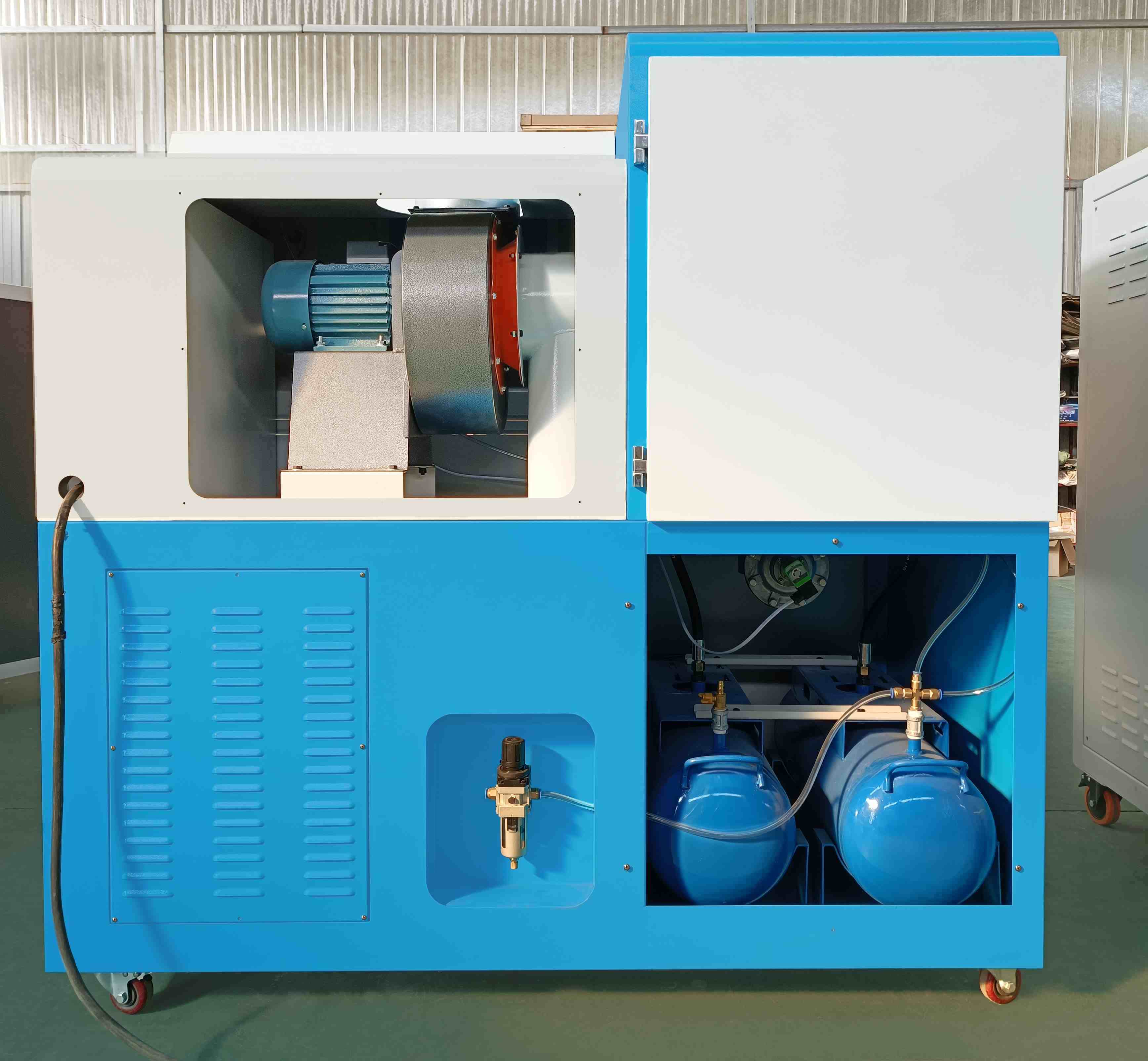

DPF SCR high temperature regeneration equipment filter cleaning machine

0086-18253885135

Equipped with pulsed purging function, it is beneficial to remove the soot attached to the carrier; with large air volume purging function, a large amount of floating dust can be blown away at once; equipped with a purging gun, it can carry out targeted purging of locally attached fumes .

During pulsed purging, the purging frequency and purging intensity can be set arbitrarily as required; when purging with large air volume, the blowing volume can be arbitrarily set as required to improve the purging effect.

The airtight purging chamber is designed to effectively remove the purging smoke and dust through a vacuum fan, and through a specially designed filter device, it can effectively collect the smoke dust and carbon ash, filter the mixed gas, and greatly reduce and eliminate environmental pollution. contamination and injury to operators. Fast, convenient, thorough and effective, hygienic and environmentally friendly.

The pipeline is designed with all stainless steel, which avoids the corrosion of the pipeline due to the humid environment, which will cause the secondary damage of the regenerated parts.

The cleaning room is brightly lit, and is equipped with an observation window, which can effectively observe the cleaned parts. The simple and easy-to-operate clamp structure is adopted, which can clamp parts conveniently, quickly and reliably.

English

English Русский

Русский Español

Español